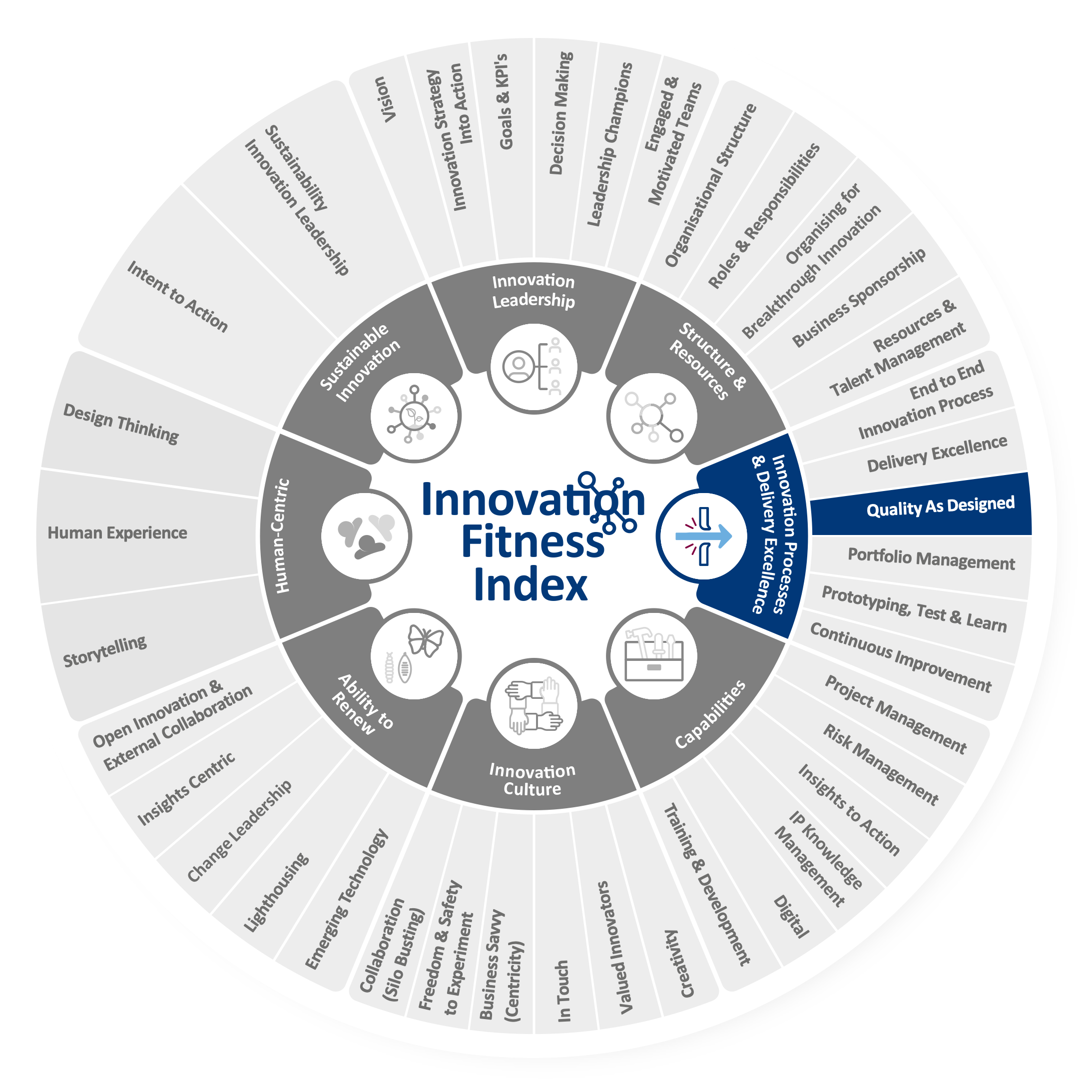

The key to sustained growth relies on an ability to innovate reliably and sustainably. At Skarbek, we are embarking on a journey to unravel the mystery behind what makes the best excel at this. Leveraging our experts’ vast experience and highlighting attributes from our Innovation Fitness Index, we aim to provide unique insights into some of the core factors impacting innovation success. Today’s article is focused on the specific Innovation Fitness Index attribute “Quality as Designed”.

The most successful innovators consistently deliver winning innovation to the marketplace as they were intended and designed, and with consistent quality provided to the end user. In today’s competitive market, approaching quality as a proactive strategy (vs. a reactive activity), is an approach that has proven to significantly impact many aspects of innovation and company success.

The estimated global cost of poor quality to business is anything from 12% to 40% of total business costs1. Making a focus on ‘Quality as Designed’ can lead to a significant improvement in delivering products to market with their intended design, at the agreed cost and with the knowledge that they can be provided consistently to the end user. After all, nobody wants to buy a product or service with inconsistent quality.

There are essentially two sides to our Innovation Fitness Index ‘Quality as Designed’ attribute. Firstly, designing the intended quality in during the development phase to meet the initial conceptual design. How many times have you worked on a project where the initial winning concept, which amazed and delighted the consumer when first shown, turned into a shadow of this as it was delivered to market? The second aspect we see sitting side by side with design integrity, is the ability to deliver this new idea at the agreed cost, at the agreed quality and being able to do that consistently, day in day out.

How do you know if you are not delivering your innovation at the quality you had planned? There are a couple of obvious metrics (like financial results not being where they should be). But how often does a company look to other critical metrics that could be symptomatic of the issue? Below we share some further metrics for consideration, as well as some insights as to how to get ahead of any oncoming issues and deliver your product as originally conceived.

Product Performance and Customer Service

Quality as Designed in production means fewer post-production issues, which translates to better product performance and customer service. When products are designed with quality in mind, they are more likely to meet customer expectations and require less customer support, thus enhancing the overall customer experience.

Cost of Quality: Investing in Excellence

The Cost of Quality (CoQ) is a “lagging metric” often overlooked in companies, that quantifies the total cost of quality-related efforts and deficiencies2. It includes costs associated with preventing defects, identifying them before products reach customers, and dealing with the aftermath of defects that do escape into the market. Visibility to your company’s CoQ gives you a sense of how good a job you are doing at delivering Quality as Designed. Investing in quality at the design stage can significantly reduce these costs, as it is far more cost-effective to prevent defects than to fix them after the fact. By focusing on quality and user delight from the outset, companies can avoid the expenses associated with rework, recalls, and damage to their brand reputation, ultimately leading to higher profitability and customer loyalty.

Feedback and Ongoing Improvement

Delivering better innovation involves listening to customer feedback and using it to improve products and services. Many companies have Customer Services departments that valiantly interact with users to address their issues and concerns. How often this data is embraced and utilised by a company in its innovation development and day-to-day business is often spotty at best! By addressing customer concerns and incorporating feedback into the design process, companies can enhance customer satisfaction and demonstrate a commitment to meeting customer needs.

Making It Happen – How can you start taking action today!?

So, what can a company do to ensure it delivers the quality consumers expect in today’s marketplace? Here are some actionable steps that could help you deliver great Design Quality and in turn will enable you to deliver great results. Skarbek Quality Management experts are at your disposal to explore what that could mean for you.

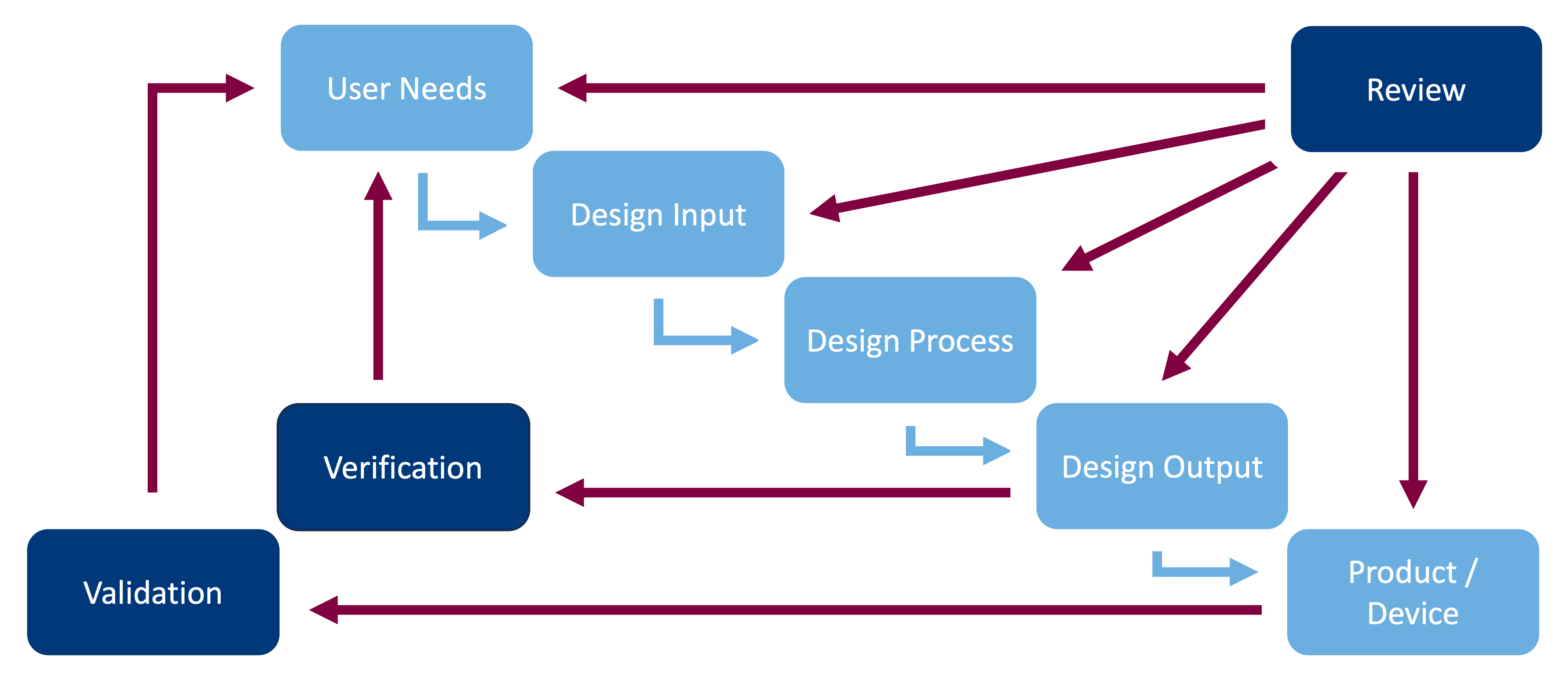

There are a few critical concepts that support what we have identified as the “Quality as Designed” attribute within our innovation model. At the heart of the insight is a systematic approach to ensuring that the desired innovation design criteria are rigorously upheld throughout the entire development process. We would argue that basing this systematic approach on the concept known as Design Control would be a key enabler. A second key insight is the empowerment of an individual(s) within the organisation to ensure that the innovation, whatever it may be, is of the highest quality and meets the required standards for the Brand/business. We have coined the term for these influential insider individuals, Internal Brand Ambassadors.

TIP ONE: Implement Design Control – A Foundation for Quality as Designed

Our first tip is to adopt a rigorous but flexible Design Control approach for your business. This approach is one of the requisites for regulatory compliance in the development of medical devices. Whilst many of the products and services that are designed and provided by companies are not regulated to such a regulated extent, there are valuable lessons companies can leverage from the concept of Design Control. We have observed that companies that leverage the principles of Design Planning (starting with the end in mind) see an improved ability to deliver the end product quality as intended, on time and on budget. Managing design changes through a Design Control Process in a planned and systematic way, ensures that Design Quality is met within a project. The challenge is for a company’s employees to embrace the quality principles in a way that the benefits of following such an approach will really lead to better results rather than slow down the innovation process. We think of it as the “slow down, to speed up” way of approaching design and delivery.

Key aspects of a benchmark design control approach in a successful New Product / Service Development process should include:

- Design and development planning – including checks and feedback loops on intended use and user needs, points of delight!

- Design output capture – including evaluation of conformance to design input requirements

- Design verification check-step – confirming that the design output meets the design input requirements

- Design validation process – ensuring that the product/service/device conforms to defined user needs and intended uses

- Design reviews – intermediate checkpoint

- Design transfer process – ensuring that the design is correctly translated into production specifications

- Design changes tracking – tracking all changes that are made

- Design history file – a demonstration that the design was developed according to the approved design plan

TIP TWO: Identify and Enable Brand Ambassadors – Elevate the Criticality of Maintaining Quality

Our second tip is to adopt the use of Internal Brand Ambassadors, who can play a pivotal role in maintaining quality standards for a brand and its commitment to quality. We have identified that successful innovation companies appoint leaders that are the custodians of Brand Quality. They are passionate advocates who use their influence to ensure that new products and services meet the required performance targets, are consistent with a brand’s message, and ensure that there is no drift in design intent from the core values and drivers of delight within a brand.

Conclusion

The benefits of Quality as Designed are manifold, impacting not just the cost-effectiveness of production but also the overall brand perception and customer loyalty. By implementing a systematic approach to Design Control, holding the innovation team to account to deliver the desired consumer experience, focusing on the cost of quality, and leveraging the power of Brand Ambassadors, companies can ensure their products meet the highest standards of delight, quality and safety. This strategic focus on quality not only safeguards against potential risks and costs, but also strengthens the brand’s reputation in the market, fostering a loyal customer base that is essential for long-term innovation success.

Quality As Designed is just one element of Skarbek’s Innovation Fitness Index, a holistic diagnostic tool, helping clients to assess how well their organisation is poised to drive innovation today. This powerful tool goes beyond conventional assessments, offering a comprehensive analysis of your organisation’s readiness to deliver innovation. It allows clients to unlock valuable insights that can shape strategy, enhance processes and elevate their innovation game. Get in touch with one of our experts to begin your innovation fitness assessment today – enquiries@skarbek.com

Sources

1. ASQ Cost of Quality

2. International Journal of Quality & Reliability Management